Visual Navigation – The Pointivo Difference

What is SmartNav™?

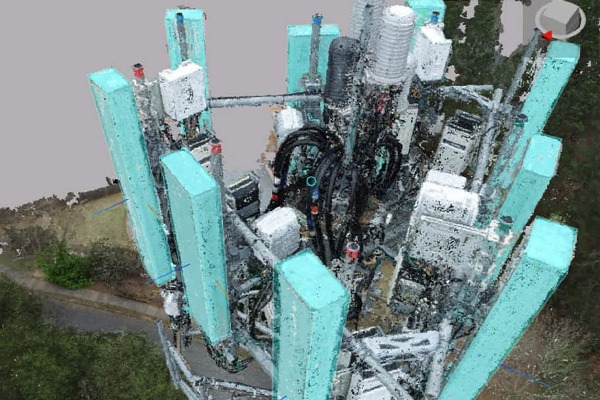

Pointivo has powered industries with AI-driven digital twin software and its patented technology for nearly a decade – having inspected over 350,000 plus complex assets using our state-of-the-art SmartNav™️ technology.

Pointivo’s SmartNav™️ technology provides precise visual accuracy in high resolution for a 360-degree virtual asset inspection. Pointivo’s digital twin and powerful AI-driven data analytics reduce errors, increase safety, and save time, travel, and expense.

SmartNav™ Features

- Virtually navigate & inspect assets across your portfolio

- 360-degree view of assets (and the entire site/compound)

- High-resolution image accuracy

- Inspect all sites/compounds and their assets from the comfort of your desk or boardroom.

- AI-driven automation

SmartNav™ Solutions

- Virtually inspects assets across your portfolio from your desk and provides a 360-degree view of all site assets to virtually navigate in high resolution as if you were there – saving time by reducing person-hours and saving on travel expenses.

- Reduces errors with highly accurate data, whereas traditional methods are highly manual and can lose or provide fragmented data, costing time and money.

- Digitizes assets for consistent, one-source-of-truth reporting across your entire ecosystem.

- Offers AI-driven automation to reduce time spent on common tasks such as auto-selecting asset areas of interest, auto-identifying common problem areas, and auto-detecting changes across time.

- You are keeping your costs down and improving margins.

SmartNav™ Advantages

As mentioned above, 360-degree virtual navigation using digital twins for physical asset inspection offers several significant benefits that can improve efficiency, accuracy, and safety in various industries.

Here are some key advantages:

- Remote Inspection: Digital twins allow inspectors and maintenance personnel to remotely navigate and explore physical assets, such as industrial machinery, infrastructure, or buildings. This eliminates the need for physical presence at the inspection site, reducing travel time and costs. Inspectors can access and analyze the digital representation of the asset from anywhere in the world.

- Improved Safety: Inspecting certain physical assets, such as those in hazardous environments or high-risk industries, can pose risks to human inspectors. Digital twins mitigate these risks by enabling remote inspection, reducing the need for personnel to enter dangerous areas. This enhances overall safety and reduces the likelihood of accidents or injuries.

- Enhanced Visualization: Digital twins provide a detailed and accurate representation of physical assets. Inspectors can navigate through complex structures, zoom in on specific components, and visualize hard-to-reach areas that might be difficult to access during traditional inspections. This improves the inspector’s understanding of the asset’s condition.

- Historical Data and Analysis: Digital twins store historical data about the asset’s performance, maintenance history, and past inspections. This data can be analyzed to identify patterns and trends, enabling more informed decision-making regarding maintenance schedules, replacement of parts, and overall asset management strategies.

- Predictive Maintenance: By combining current visual conditions and deficiency data with historical information, digital twins enable predictive maintenance. Algorithms can be applied to the data to forecast when specific components might fail or require maintenance. This approach maximizes asset uptime and minimizes unplanned downtime.

- Collaboration and Knowledge Sharing: Digital twins can be accessed and navigated by multiple stakeholders, including inspectors, engineers, and maintenance teams. This fosters collaboration and knowledge sharing, as experts from different locations can collectively examine the asset, discuss potential issues, and jointly arrive at solutions.

- Reduced Downtime: Traditional inspections often involve shutting down assets for inspection, leading to production downtime and revenue loss. Digital twin-based inspections can be carried out while the asset is operational, minimizing disruptions to normal operations.

- Cost Savings: By reducing the need for on-site inspections and optimizing maintenance schedules, digital twins can lead to significant cost savings. Timely maintenance interventions based on accurate data can also extend the lifespan of assets, reducing the need for premature replacements.

- Documentation and Reporting: Inspections conducted using digital twins generate detailed visual documentation. This documentation can be used for audit purposes, compliance reporting, and regulatory requirements. It provides a clear record of the asset’s condition at specific points in time.

See the difference for yourself. Contact us at team@pointivo.com.

[tags]