Comprehensive Analysis of Computer-Aided Design with AI-Driven Analytics

The Benefits of Integrating CAD with Drone-Based Analytics

Background and Technological Integration

Computer-aided design (CAD), a fundamental tool in design and engineering, enables the creation and modification of 2D and 3D models. Drones, equipped with high-resolution cameras and sensors, capture detailed visual data from structures, particularly in hard-to-reach or hazardous areas. AI-driven analytics software processes this data, identifying features, measuring dimensions, and generating 3D models with high precision. The integration occurs as follows:

- Data Capture: Drones fly over the inspection area, collecting hundreds or thousands of images. Depending on size and application, a single drone flight can capture building data in roughly 30 minutes.

- AI Processing: The captured data is uploaded to AI software, which processes it to identify features (e.g., installed equipment), measure distances, and create 3D models or digital twins. This step can be completed within 24 hours or less.

- CAD Utilization: The processed data can then be exported into several CAD-compatible formats, including IFC and DXF formats, facilitating import into CAD software. This allows engineers to compare as-built conditions with original designs, plan repairs, or simulate modifications. For instance, Pointivo’s platform enables exporting drone-captured inspection data directly into CAD programs using industry-standard formats such as IFC and DXF.

Benefits of Integration

The synergy of CAD, drones, and AI offers significant advantages, supported by industry data:

Efficiency: Traditional modeling of as-built structures can take days or weeks, but drone-based methods reduce this dramatically. The approach ranges from 60-90% faster than manual measurements, saving substantial time. Modeling times are reduced from days to hours, just the time it takes to capture the drone imagery and wait for the automated processing to complete.

Accuracy: Drone-captured data, coupled with AI-driven visual software, enhances precision by detecting minute details. Measurements are up to 8x more accurate than manual processes, with accuracy over 99% and tolerances as tight as 1.5mm. AI-powered damage detection identifies damage requiring repairs across various asset types with high precision, reducing errors.

Safety: Drones eliminate the need for human inspectors to access dangerous areas, such as tall structures or energized environments. This is particularly beneficial in utilities and construction, where drone inspections reduce risks to workers.

Cost Savings: Reduced labor costs and fewer accidents lead to financial benefits. Industrial drone program adoption is growing at a 66.8% compound annual growth rate (CAGR), driven by cost-effectiveness.

Seamless Workflow: Direct integration with CAD ensures that inspection data can be immediately used in design and planning. Pointivo’s drone inspection services provide data that can be input into mount analysis software in under 30 minutes, for example, streamlining workflows.

Use Cases Across Industries

The integration is applicable across various sectors, with specific applications:

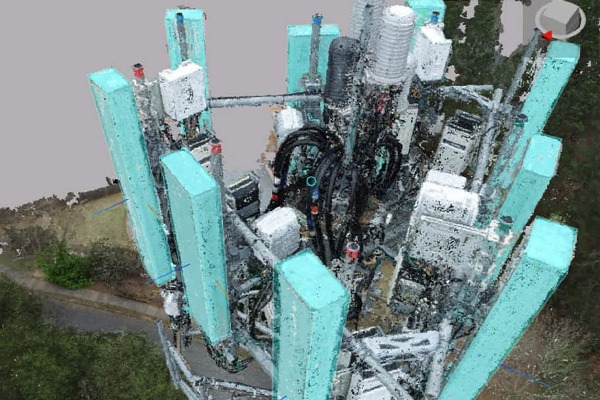

Infrastructure – Regular inspections for telecom towers and other critical infrastructure are made safer and more efficient. Pointivo creates digital twins of towers using drone data, enabling precise measurements and structural analysis for CAD integration. Clients often use drones for infrastructure inspections, potentially linking with CAD for maintenance planning.

Roofing – Pointivo’s AI-driven analytics detect damage and generate analytics exportable to CAD for repair planning or solar installation design. The platform reduces laborious manual inspection time to a simple review of just five to ten minutes.

Effective Data & Implications

Real-world examples and statistics underscore the effectiveness:

- Drones on the market paired with AI-driven visual inspection platforms provide 3D measurements with up to 99.9% accuracy, saving 60%-90% of the time compared to traditional methods.

- Pointivo’s AI-driven visual inspection platform reduces roof inspection time to five to ten minutes, with AI highlighting damaged areas for quick review, offering full measurements, exportable to any CAD program. Utilizing AI to interpret drone imagery for progress monitoring, maintaining, and defect detection, which can be integrated into CAD workflows. They reduce the need for manual inspections, enhancing safety.

This comprehensive analysis demonstrates that the integration of CAD with drone capture and AI-driven analytics is a game-changer, offering a robust solution for modern engineering and design needs.

To learn more about Pointivo’s AI-driven platform and reporting capabilities, contact us at team@pointivo.com.

Don’t forget to share this post!

[tags]