Although the term “digital twin” has become a popular buzzword in the telecom infrastructure space, it is often misused. This causes confusion and can impede an organization’s path to digitization. I will clarify what digital twins are, provide context for how they are applied in telecom, and offer best practices for deploying an effective digital twin strategy.

The term “digital twin” is relatively new, with the first software applications being designed for manufacturing in 2002. However, the concept of using a “twin” as a means of studying a physical object can be traced all the way back to space exploration missions of the 1960s, when NASA created exact replicas of each voyaging spacecraft for study and simulation purposes. Famously, the technology was used in April of 1970 to rescue Apollo 13 after a disastrous explosion of its oxygen tanks. NASA’s engineers used a “twin” of the command module’s electrical system to devise steps to power up the frozen spacecraft without draining the remaining power in the batteries. The solution was completed with the twin in two hours instead of the two days it normally took on the launchpad.

There are many definitions of a digital twin. A common definition by IBM defines a digital twin as “a virtual representation of an object or system that spans its lifecycle, is updated from real-time data, and uses simulation, machine learning, and reasoning to help decision-making.”

That definition may sound more involved and complicated than you may have expected with the inclusion of simulation and real-time data. This is because the term has grown up in industries such as automobile manufacturing, aircraft production, industrial systems, and power utilities. For those industries, a digital twin was developed to optimize real-time operations or enable engineers to simulate scenarios without physically adjusting production systems. In the telecom space, similar applications could be developed for network operations, for example: planning and building, monitoring, maintenance, or energy planning and capacity management. However, to effectively implement such a digital twin solution in telecom would require monitoring end-to-end network performance from radio access to transmission to the core. This would be prohibitively expensive and therefore is not the prevailing focus of digital twin technology in telecom.

A more general definition from the Digital Twin Consortium describes a digital twin as “a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity…to transform business by accelerating holistic understanding, optimal decision-making, and effective action.”

This definition, relieving us from simulation and real-time data requirements, lends itself to practical uses of digital twins in telecom today – solving problems around discrete tower management.

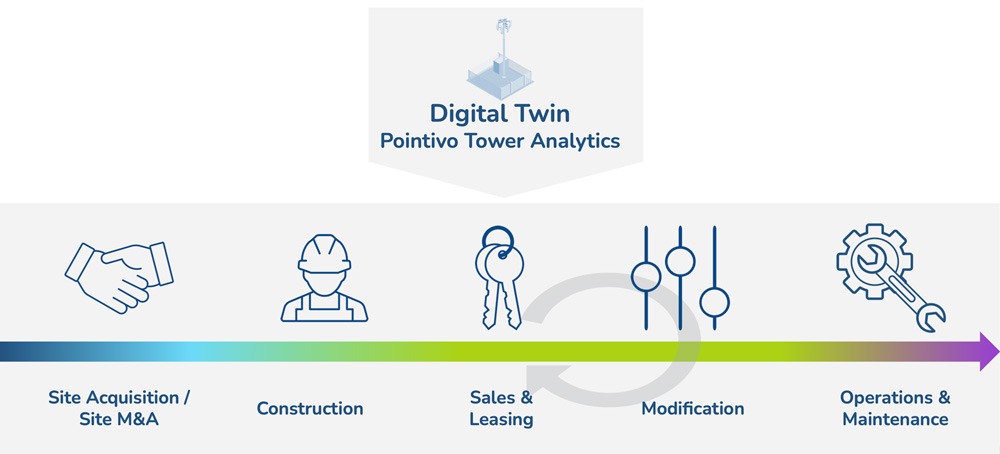

“The digital twin delivers a highly accurate virtual representation of a telecom tower site, with data updated just before it is needed, accelerating processes and improving optimal decision-making along the entire tower management lifecycle.”

We utilize drones and other sensors to collect data from tower sites and make it available in the cloud as a digital twin model. This includes integrated machine learning-based analytics to support decision-making across the organization. At the core of the virtual representation is a highly accurate 3D model, a detailed visualization of a tower in three dimensions. One source of confusion in the industry is the difference between a 3D model and a digital twin, often perpetrated by 3D model vendors wanting to get into the digital twin space. The digital twin of a tower is not just the digital visualization. It also includes a much richer set of details about every aspect of the tower. It is seamlessly and frequently refreshed, and is integrated with AI-driven processes that deliver real business value.

A properly implemented digital twin solution can transform business processes across a telecom organization along all phases of a tower lifecycle.

Examples include:

- Site selection: network engineering teams can base decisions on accurate data without everyone having to visit the site.

- Sales & Leasing: auditors know what is deployed on the tower and the sales and leasing department knows exactly what space is available, and can share access with carriers in real time.

- Construction/Modification: engineering teams can generate plans and drawings, generate structural and complete post-construction audits without anyone having to visit the site.

- Operations & Maintenance: engineering teams can perform maintenance and condition assessment and track TIA issues without accessing the site.

A digital twin establishes a shared set of data across an organization, removing typically siloed and restricted sets of outdated information. The knowledge once available only to the IT department expands into business groups, internal operations, and customer relationships. Access to the data enables employees across an entire organization to optimize their decisions and processes. Repetitive processes can be automated with a digital twin, allowing more focus on delivering value across the organization and customer base.

Implementing a successful digital twin strategy is challenging but achievable.

Critical components of a successful strategy include:

- Operational processes to continually collect and update data

- Central data repository integrated into existing systems

- Digital workflows that carry data insights to where they’re needed in operations

- Organizational champion who can drive the solution across the organization

Operational Processes

A critical aspect of a digital twin solution is including accurate and current data. The initial effort of digitizing a portfolio and frequently refreshing the data requires strong operational processes. Whether an organization chooses to develop an in-house data collection program, uses outsourced resources, or deploys a drone-in-a-box solution, it is critical to ensure consistent and accurate data capture and seamless integration of updates. Delivering accurate data in a repeatable and proven manner, at scale, requires expertise that few organizations or vendors have. A few telecom innovators have proven it is possible to continually collect and process hundreds of towers a day. Some early innovators have shut down drone programs because their vendors could not reliably deliver consistently accurate results. Choosing the right partner who has experience with this level of scale is important to the success of a program.

Central Repository

A central repository is critical to ensure that the digital twin is a single source of truth across an organization. The digital twin repository must integrate with existing backend and downstream systems to support a single consistent view across existing processes and data stores. An important benefit some early adopters have realized is that a properly integrated twin solution with machine learning algorithms will cleanse entire legacy systems; something rare in today’s world.

Digital Workflows

Digital twins can only be useful if they, and their related analytics, are available and accessible at their highest value points. For example, the engineering department must know that the digital-twin-based mount data flowing into structural analysis is current and accurate when it is needed. Construction documents tied to the twin must seamlessly travel from permitting to construction and post-construction processes. The digital twin solution is most successful as part of a full digitalization strategy.

The Champion

One of the most important aspects of a successful digital twin strategy is a champion within an organization who can select the right partners, share best practices, and evangelize across the organization, explaining how a digital twin and advanced analytics can accelerate business processes. Behind every successful digital twin strategy is a champion who has support and trust at the highest levels of an organization.

Digital twins have advanced from simply a buzzword to a transformational technology in the telecom infrastructure space. Properly implementing digital twins is challenging but can accelerate business processes across the entire tower management lifecycle. The benefits can extend across the organization and to customer relationships. As digital twins move from the early innovators to widespread adoption, we will finally see true progress in the digitization of the telecom industry.

The Digitization of the Tower & Roofing Industry

Want to see how augmenting your resources with drone automation will impact your business?

About the Author

Dan Ciprari is CEO and co-founder of Pointivo.

Pointivo is the leading AI analytics platform for digital twins and physical asset inspection. Pointivo was founded eight years ago with the vision to automate analytics using its patented AI and computer vision platform. As Pointivo has been at the forefront of the commercial drone industry, Pointivo has focused solely on providing digital twins with advanced analytics in support of customers and partners transforming their industries. Pointivo has grown to be #1 in telecom, roofing, and facilities analytics generating digital twins for over 200,000 assets, and is expanding to energy, utility, and infrastructure markets. Given its early entry in the space, Pointivo’s extensive patent portfolio gives it broad ownership of many of the enabling technologies required to drive the growth and future of digital twins and automated asset inspection. See Dan’s related blog on The Past, Present, and Future of Drones and Asset Inspection.