The Benefits of 3D, AI-Driven Software, & Drone Data Capture in Construction Defect Investigations (CDI)

Digital Technology for Construction

In the construction industry, precision is paramount. Whether it’s a large commercial building, a residential complex, or a public infrastructure project, even the smallest defect can lead to costly repairs, legal disputes, and delays. Traditionally, Construction Defect Investigations (CDI) have relied on manual inspections, which, while useful, are often slow, labor-intensive, and subject to human error.

Today, technological advancements are changing how construction professionals handle these investigations. Tools like 3D modeling, AI-driven software, and drone data capture have changed how construction defects are identified, analyzed, and resolved. These technologies offer greater accuracy, efficiency, and cost savings, providing substantial benefits for contractors, property owners, and insurers. Below, Pointivo explores how we can enhance the CDI process which includes an effective use case.

What is CDI?

A construction defect investigation (CDI) is a process that identifies and analyzes defects in a building. Defects can be minor, cosmetic issues or structural issues, but they can significantly impact a property’s safety and value.

CDIs are important for several reasons, including:

- Protecting the property’s value

- Ensuring the safety of the property’s occupants

- Complying with legal construction contract provisions and warranties

Documentation & Evidence

Collecting and organizing relevant and accurate documentation, including plans, specifications, contracts, and change orders, is essential for establishing the scope of the project and understanding the potential areas of defect. Physical evidence such as samples and photographs must support findings. Accessing and analyzing vast amounts of documentation and evidence can be time-consuming and requires meticulous attention to detail.

Traditional CDIs: A Time-Consuming Process

Before the rise of digital tools, CDI was a labor-intensive, time-consuming process that involved on-site inspections by experienced professionals. These inspections often required extensive setup, such as scaffolding for accessing high or difficult-to-reach areas, and could take days or even weeks to complete, depending on the size and complexity of the project.

Once defects were identified, manual measurements, photographs, and written reports would be compiled, often leading to delays in analysis and problem resolution. Furthermore, many defects were not immediately visible, and some issues were missed entirely until they escalated into major structural concerns.

The Impact of 3D Modeling, AI-Driven Software, and Drone Data Capture on CDI

The introduction of 3D modeling, AI-driven software, and drone data capture has dramatically improved the CDI process, making it more efficient and effective. These technologies enable construction teams to identify and resolve defects faster, with fewer resources and greater accuracy.

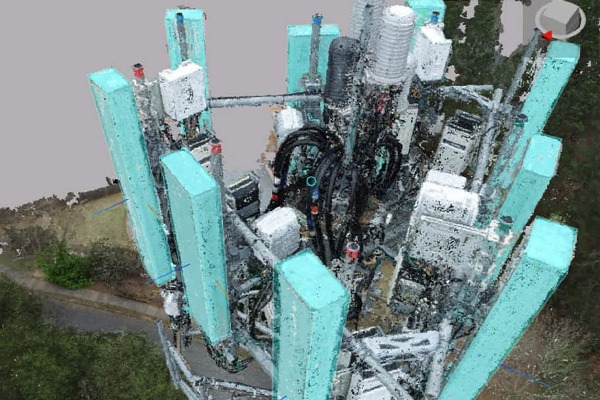

1. Drone Data Capture: Expanding the Reach of CDI

Drones have become a game-changer in the construction industry, particularly for construction defect investigations. Equipped with high-resolution cameras and various sensors, drones can capture detailed visual data of a building’s exterior, roof, and other hard-to-reach areas. This eliminates the need for scaffolding or manual inspection in dangerous or challenging environments.

Key benefits of drone data capture include:

- Improved Access: Drones can fly over large or tall structures, accessing areas that are difficult or unsafe for human inspectors.

- High-Speed Inspections: Drones capture images and videos in a fraction of the time it takes for traditional manual inspections, allowing for faster analysis and reporting.

- Cost Efficiency: By reducing the need for scaffolding, ladders, or cranes, drones help lower the overall cost of inspections, especially for large projects.

According to PwC, using drones for inspections can reduce the time required for the process by 80%, while also cutting costs by 30-50% compared to traditional methods.

2. AI-Driven Software: Enhancing Accuracy and Speed

The data captured by drones is incredibly valuable, but it’s in the analysis of that data where the real improvements occur. Pointivo’s AI-driven software processes the raw data, identifying patterns, predicting potential defects, and providing actionable insights. In construction defect investigations, AI can quickly analyze drone imagery and 3D models to detect structural issues, water leaks, material defects, and other problems that could be missed during a manual inspection.

AI software provides several advantages:

- Automated Defect Detection: AI algorithms can identify issues such as cracks, misalignments, or moisture intrusion faster and more accurately than human inspectors.

- Analytics: By continuously learning from the data it processes, AI-driven software can eliminate potential future defects, by enabling proactive maintenance and reducing long-term repair costs.

- Consistent, Objective Analysis: Unlike human inspectors, AI systems do not get fatigued or overlook details, providing consistent, objective results with every investigation.

According to McKinsey, AI-driven predictive maintenance strategies can reduce maintenance costs by 10-40% and minimize unplanned downtime by up to 50%.

3. 3D Modeling: Visualizing Defects in Real Time

3D modeling provides a detailed and immersive visualization of a building, giving construction teams, property owners, and insurers a clear, accurate view of the structure. Using drones and sensors, 3D models are generated in real-time, allowing inspectors to virtually “walk through” the building and examine its components from multiple angles.

With 3D models, stakeholders can compare the building’s current state to its design plans, making it easier to identify discrepancies or defects that need immediate attention. This technology also enables before-and-after comparisons, which are critical for documenting the progress of repairs and ensuring that defects are fully addressed.

Benefits of 3D modeling include:

- Precise Visualization: 3D models provide a clear, accurate view of a building’s structural integrity, allowing for more informed decision-making during CDI.

- Collaboration and Communication: These models are easily shared with all stakeholders, facilitating better communication between contractors, property owners, and insurance companies.

- Enhanced Documentation: 3D models create a permanent record of a building’s condition at any given time, making it easier to track the development of defects or repairs.

A report by Deloitte found that the use of 3D modeling in construction defect investigations can reduce repair costs by 20-30% through early defect detection and improved communication between stakeholders.

Use Case: Large Commercial Building Defect Investigation

A real estate development firm managing a large commercial building faced potential structural defects after the building was completed. Minor cracks had appeared in the facade, and water leakage was reported in certain areas. The firm was concerned that these issues could lead to long-term structural damage if not addressed immediately. Rather than resort to traditional, time-consuming manual inspections, the firm opted to use drones, Pointivo’s AI-driven software, and 3D modeling for the investigation.

Here’s how the technology was applied:

- Drone Deployment:

- Drones equipped with high-resolution cameras were deployed to capture detailed visual data of the building’s facade and roof. This was done within hours, eliminating the need for scaffolding and manual inspection.

- AI Analysis:

- The captured drone footage was fed into Pointivo’s AI-driven software, which quickly identified cracks, water entry points, and potential material failures in the building’s exterior. The software also compared the current condition of the structure to its original design specifications, identifying areas where construction may have deviated from the plan.

- 3D Modeling:

- Using the data from the drones, a comprehensive 3D model of the building was created, allowing the inspection team and the property owner to virtually navigate the entire structure. This enabled them to visualize the defects in real time and prioritize repairs based on the severity of each issue.

The Results:

- The investigation, which would have taken weeks using traditional methods, was completed in just three days.

- Pointivo’s AI software detected minor cracks and water infiltration points that were invisible to the naked eye, preventing further damage.

- The detailed 3D model allowed the property owner to communicate the findings with contractors and insurers, expediting the repair process.

- The proactive approach, driven by digital technology, saved the firm an estimated $500,000 in potential repair costs and litigation fees.

Long-Term Benefits for CDI

The use of 3D modeling, AI-driven software, and drone data capture isn’t just about solving immediate problems—it’s also about long-term efficiency and cost savings. These technologies enable property owners and construction teams to take a proactive approach to defect detection and maintenance, minimizing the risk of structural failure, costly repairs, and legal disputes.

Key long-term benefits include:

- Reduced Inspection Costs: By automating parts of the inspection process, property owners save on labor costs and reduce the need for repeat inspections.

- Improved Asset Management: Regular digital inspections help extend the lifespan of buildings by identifying potential defects early and enabling timely repairs.

- Better Documentation: The data captured through drones, AI analysis, and 3D models create a digital archive that can be referenced at any time, making it easier to track the history of a building’s condition.

- Enhanced Compliance: Many local building codes require regular inspections of certain structures. Digital tools help ensure compliance by providing thorough, accurate reports that can be easily shared with regulatory bodies.

Incorporating 3D modeling, AI-driven software, and drone data capture into Construction Defect Investigations (CDIs) marks a significant leap forward in the construction industry. These technologies streamline the inspection process, improve accuracy, and provide valuable insights that can prevent small issues from becoming major problems. For contractors, property owners, and insurers, adopting these tools can lead to substantial cost savings, enhanced project outcomes, and a stronger overall approach to managing construction defects.

Digital technologies allow the construction industry to move away from reactive inspections and toward a proactive, data-driven approach that ensures higher-quality builds and more secure, lasting structures.

To learn more about Pointivo’s AI-driven platform and reporting capabilities, contact us at team@pointivo.com.

Don’t forget to share this post!

[tags]