Optimizing Capital & Operating Expenses

with Tower Inspections

Summary & Introduction

The telecommunications industry’s relentless evolution necessitates an efficient, cost-effective approach to maintaining its backbone – telecom towers. Traditional tower inspection methods fall short in terms of safety, cost-efficiency, and accuracy. Pointivo explores the significance of harnessing AI-driven digital twin technology to revolutionize tower inspections in the telecom industry utilizing drone capture. This combination can enhance networks’ safety and reliability and yield substantial financial benefits by optimizing capital and operating expenses.

The telecommunications industry is experiencing unprecedented demand for connectivity and data transfer. Regular inspections are indispensable to maintain the robustness and reliability of this expansive network. Historically, these inspections have been labor-intensive, costly, and potentially risky for personnel.

The Telecom Industry's Critical Need for Tower Inspections

Telecommunication towers form the foundation of the industry, facilitating wireless communication networks that connect people, devices, and data. Regular inspections are essential to:

- Identifying structural issues that may compromise tower stability.

- Inspecting site compounds such as rooftop surveys and interiors using Matterport or LiDAR data.

- Auditing carrier inventory which is critical to revenue generation.

- Detecting malfunctions or anomalies that could lead to service interruptions.

- Ensuring compliance with safety and regulatory standards.

Challenges in Conventional Tower Inspection

Conventional methods of tower inspection have long been fraught with challenges:

- High Costs: Traditional inspections necessitate specialized personnel, equipment, and expensive personnel travel time and expenses.

- Safety Risks: Tower climbs present substantial risks to technicians, which can result in accidents, injuries, and death.

- Inefficiency: Manual inspections are time-consuming, require multiple personnel, and frequently require multiple visits to towers to gather comprehensive data.

- Data Accuracy: Human error in data collection and reporting can compromise the quality and reliability of inspection results.

Drone Capture for Tower Inspections

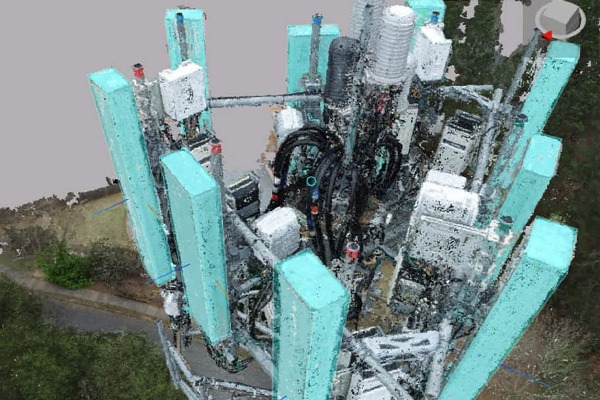

The adoption of drone technology for tower inspection has revolutionized the telecom industry. Drones with advanced cameras and sensors can capture high-resolution imagery and data from numerous angles, heights, and positions, providing a holistic view of a tower’s condition. Integrating Pointivo’s AI-driven digital twin technology improves efficiency and insight into critical physical asset inspections using either in-house drone personnel or contracted drone service providers.

Pointivo’s AI-driven Digital Twin Technology

- A patented scale marker system is used for automatically scaling and orienting the digital twin, which includes the entire tower, mount structures, RAD centers, all appurtenances, and compound equipment.

- Engineering-grade accuracy in all measurements

- SmartNav™ technology with synchronized virtual navigation between the digital twin and high-resolution imagery.

- A solution that leverages AI-driven detection and identification of all installed equipment through the equipment’s geometric and visual characteristics.

- A variety of filtering options that include size, make, and model parameters to narrow down the choices for a specific object/equipment in a scene.

- Industry-best practices for data storage and security, including data encryption at rest, regular database backups, and bucket versioning.

Integration of Drone Capture & Pointivo’s AI-driven Digital Twin Technology at Scale

Benefits of Combining Drone Capture and Pointivo’s AI-driven Digital Twins

- Scalability: For achieving the goal at scale, including all legacy sites globally, it is essential to have an automated tool for creating a granular 3D model of site topology and an asset catalog in a format compatible with the BIM.

- Accuracy: High-resolution imagery with Pointivo’s patented scale markers and automated analysis provide precise scaling and orientation of the digital twin for engineering-grade measurement accuracy and detailed inspection results.

- Consistent Data Capture: Repeatable image capture procedures and automated flight solutions optimize processing and ensure the generation of highly accurate models.

- Safety: Minimizes the need for technicians to physically climb towers, reducing the risk of accidents and injuries.

- Efficiency: Drones can inspect towers quickly and thoroughly, saving time and resources. An automated flight plan setup takes 1-2 minutes and can be executed in as little as 20 minutes by a single person. This allows for a considerable amount of towers to be captured each day and achieve a high run rate of digitization.

- Cost Savings: Reduced labor and equipment costs make drone inspections cost-effective.

Financial Implications: Impact on Capital Expenses

- Improved Decision Making: Easily access and analyze data with one source of truth across multiple stakeholders. Enhancing communication and collaboration improves project ROI by 47%.

- Reduced Infrastructure Spending: The need for expensive climbing equipment and personnel is diminished, resulting in lower capital expenses. Adapting automation lowers administrative costs by 30%.

- Optimized Maintenance: Predictive analysis through digital twin technology ensures that maintenance is only performed when needed, reducing unnecessary spending on maintenance while ensuring the most critical issues are addressed before they become larger problems.

- Revenue Growth: Adapting digitization management enables sales teams to understand available space and allows prospective tenants to view sites virtually while tracking assets across multiple locations and projects, even if they are geographically dispersed, gaining an average of 20% increase in revenue.

Operational Advantages: Impact on Operating Expenses

- Reduced Labor Costs: Lower reliance on technicians for physical inspections translates into significant labor savings.

- Decreased Downtime: Carriers experience less downtime as issues are addressed proactively, reducing operating costs associated with network outages.

- Increased Efficiency: Streamlining operations by automating manual processes reduces the risk of errors and can lead to improved profitability.

- Verification of Asset: Verify tower condition for pre-planning to assess defects and connectivity conditions and locate assets. In addition, ensure all is delivered and installed as designed.

Case Studies: Realizing the Potential

- Case Study 1: A major tower owner reduced inspection costs by 40% and helped the carrier increase uptime and performance by 25% after implementing drone capture and digital twin technology.

- Case Study 2: A mobile operator reduced the number of tower climbs by 75%, resulting in a 30% decrease in operating expenses.

Compliance and Safety

- BIM Formatting: Functionalities for generating BIM-compliant 3D models with different levels of detail for varying asset types.

- Enhanced Reporting: Accurate data collection and reporting are vital for ensuring compliance with industry regulations.

- Safety Measures: Reduced reliance on tower climbs decreases the potential for accidents and safety violations.

Future-Proofing Telecom Infrastructure

- Facilitating Predictive Maintenance: Predictive algorithms within digital twins anticipate and prevent failures, reducing downtime and operational costs.

- Real-Time Monitoring: Digital twins provide real-time data on tower conditions, allowing for proactive maintenance.

- Remote Troubleshooting: Stakeholders can remotely assess issues and make more informed decisions.

- Scalability: Automation, AI’s computer vision, and cloud-based applications future-proof operating and capital expenses.

Conclusion

Recommendations

- Determine the investment stage for in-house drone technology and training for their personnel vs. contracting drone operators. (See video beginning at 18:00)

- Implement Pointivo’s patented, AI-driven digital twin technology to create virtual replicas of their tower assets.

- Develop and integrate predictive maintenance algorithms into their digital twin systems.

- Continuously monitor and optimize their tower inspection and maintenance processes.

By following these recommendations, telecom companies can ensure their physical assets infrastructure’s longevity and reliability while simultaneously generating a precise single source of truth across diverse teams, reducing costs, and improving their bottom line. The future of telecom tower inspections is here, and it is both efficient and cost-effective.

To learn more about Pointivo's AI-driven digital twin technology for carriers, tower owners, and engineers contact us at team@pointivo.com.

Don’t forget to share this post!

[tags]