By J. Sharpe Smith, Inside Towers Technology Editor

Not that long ago, a closeout package for tower services work entailed a few dozen pictures of the deployment on the tower, each of them labeled with proper paperwork. The closeout would be submitted during the post-construction phase of work as a hard copy, sent to the carrier in hopes that all correct views were included, according to Alex Daly, Vice President of Technical Services at Network Building + Consulting (NB+C).

“As a company, we are always trying to figure out how we can do things faster and cheaper, and with higher quality,” Daly said. “We needed a way to create the closeout data more efficiently.”

Times have changed for NB+C, as the company now works with every major wireless carrier and tower company. Additionally, the company works with fiber providers and utility companies from early-stage project planning to engineering and construction. With this volume, NB+C now uses drones to take photographs of its deployments, leveraging a tower-specific automated flight solution provided by Pointivo. Today, carriers receive more information concerning work done on towers than ever before and more quickly, as well, according to Jacob Garland, CTO, Pointivo.

“The ability to capture images from a drone of a structure can give you a lot of information, a lot of imagery. But what do you do with all of that imagery?” Garland asked. “Pointivo’s vision for the industry is to let the complexities of drone technology fade into the background and allow customers to derive real-world benefits from that technology. Drones and the data they can capture are a powerful new tool in the tower engineer’s toolbox.”

Pointivo offers a cloud-based software platform that analyzes high definition imagery from drones to identify and extract location, measurement and detailed understanding about physical assets and structures, with the highest-level accuracy.

“Pointivo applies patented 2D and 3D analytics to help engineers, architects and asset owners solve real business problems associated with inspection, inventory, and assessment of physical assets. We combine AI, computer vision and machine learning to drive deeper understanding of physical structures such as cell towers,” Garland said.

Post-construction analysis begins with a pilot taking the drone up for a 30-minute flight. The unmanned aerial vehicle marks the top of the tower, then completes several passes around the structure, scanning it in its entirety, while taking hundreds of pictures.

“Let’s say that we’re looking at an install for one of the carriers,” Daly said. “We are looking to document the newly deployed antennas, RAD center, mounts and cables, all of the components that show the equipment was installed properly.”

All the imagery is updated to Pointiivo’s platform, which quickly generates an accurate digital twin of the tower and identifies all the equipment, using AI-powered analytics.

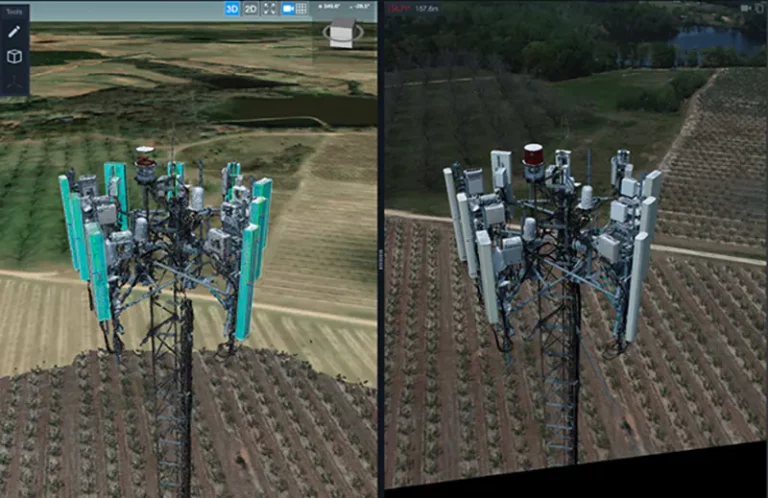

With equipment displayed in its patented 3D visualization engine, Pointivo Tower Analytics enables a user to very quickly confirm proper deployment of the antennas, RAD center, mounts and cables. And if the tower was flown pre-construction, the system will make it even easier by highlighting and documenting, down to equipment model, every change to the tower.

Additionally, when an engineer needs to check another measurement or validate another component against construction drawings, the engineer can simply access the digital twin, reducing windshield and repetitive field time and costs. With these features, Pointivo makes the post-construction process significantly more accurate, efficient, cheaper and safer for companies like NB+C.

“A digital twin is more than just a 3D model that someone has generated from imagery. It is a representation of a real-world physical asset that has all of the semantic properties of that real world object. Looking at a digital twin gives you the feeling that you are floating in space next to the actual tower,” Daly said. “You’re able to take that tower and rotate one way, get into an area, and zoom in. Then twist another way, turn it and zoom into another section. Literally, there are thousands of views and angles that are now available to you, and they’re not going away.”

The 3D visualizations are a world away from the days when tower services companies took dozens of pictures of their deployments on the tower, labeled them and checked all the boxes of the closeout package.

Pointivo’s tower-specific automated flight solution meets real-world fixed measurements, creating levels of accuracy of less than a half a centimeter over a 100-meter distance. “We can achieve highly precise, engineering-grade measurements on these towers,” Garland explained.

RF engineers can also utilize the digital twin to determine if the antenna was installed properly and if the tower is going to perform exactly as they modeled it. The digital twin can deliver information that has previously only been achieved by putting someone on a tower, according to Daly.

“The accuracy of the digital twin is just ridiculously high,” Daly said. “The reality of it is, when you get into this 5G technology and the higher spectrum bands, there is a greater need for accuracy. There is little margin for error. You get much higher quality, and you are out there for less time. It’s much safer, because I don’t have two guys climbing it, trying to rush because they need to get to that other job.”

Pointivo blends the worlds of three-dimensional and two-dimensional data, which allows the user to view the tower as though they were standing on it real-time. “From the technology side, it’s really exciting to see the real world business applications and allow people to get their jobs done faster, safer and more accurately in the process,” Garland said.

The use of cell tower drone inspection services has grown to the point where it spans every government entity, wireless carrier and tower owner. With the use of Pointivo’s Tower Analytics software, closeout documentation during the post-construction phase of an install has risen to a new level of speed and accuracy.

“This is one of the ways construction companies and site development companies like NB+C are adapting to meet the carriers’ needs,” Daly said. “I keep going back to those three words — faster, cheaper and with higher quality.”

For more information about NB+C visit: https://www.networkbuilding.com.